Açıklama

Milk Pet Bottle Filling And Capping Machine

Milk pet bottle and filling capping machine

3-5 lt Milk Filling Machine

Pet bottle fresh milk filling and capping machine is the most demanded product among

milk filling machine group. It is used for filling, capping and labelling for 3-5 lt pet bottles.

Together with the increase in fresh milk consuming; pet bottle raw milk filling and capping

machines are demanded often by factories and dairy farms processing milk and milk products.

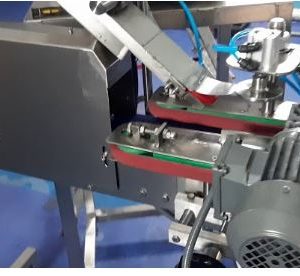

Raw milk filling and capping machines are linear operating. After filling with flowmeter,

capping, safety closure and labelling; it becomes ready for shipment.

Demand Evaluation

Milk filling and capping machines are designed in accordance with customer requirements.

Pet bottle to be filled, daily filling capacity, safety closure and label properties (one or two sided)

are the criteria taken into account in the design phase of the pet bottle milk filling and capping

machine.

Design Phase

During the design phase of the milk filling machine, machinery drawings are prepared by technical

draftsman by taking the mentioned points into consideration. Starting from this drawing; meetings

are made by technical team to achieve the final design before starting the production phase.

Production Phase

Production phase of the pet bottle filling machine is being handled with coordination between

technical teams. Products and half-products whose procurement phase has been completed are

produced in a fastest way in accordance with the production line status and goes through several

testings before the shipment to the customer.

Operating Principle

Pet Bottles are located on a linear conveyor manually or by means of robot sequencers are

subjected to filling by nozzles defined in accordance with the filling capacity (4-6-8…). After

the completion of milk filling process, capping is applied to the pet bottles by the help of a

vibration machine.

If required; capped bottles can be taken through heat tunnels after placing of safety closure

(heat shrink tube). After the safety closure covers the bottle firmly by the heat effect, if required;

bottles are labelled by the labelling machine located at the end of the line. After this, they

are collected in the collecting tray.

What Can Be Filled With This Machine?

It is possible to make filling for pet bottle milk filling, pet bottle ayran filling, pet bottle vinegar

filling, pet bottle kephir filling, etc in addition to liquid substances such as anti-freeze, windshear

washer fluid by using this machine whose properties are defined above.

https://www.tetrimak.com/video-gallery-tetrimak-makine-filling-machine/

https://www.expogi.com/dolum-ve-paketleme-tetrimak-makine.html/

Joseph Karlof –

It is an extremely healthy application to fill daily milk with pet bottle milk filling and sealing machines. Products sold without bottling are likely to cause harm to human health.